- Home »

- Component supplier »

- ASYST

ASYST

At ASYST Technologies, we believe in the power of collaboration, innovation, and commitment. We’re more than just a plastic injection molder, we're a team of passionate innovators, problem solvers, and partners, dedicated to helping you achieve your manufacturing goals. We've built a reputation of excellence in the automotive industry, but our expertise extends much further. With decades of experience in product development, injection molding, assembly and automation, we offer a wide range of solutions, all crafted with precision and backed by our stringent quality systems. We work hand-in-hand with our clients from concept to commercialization, we support you at each stage of the process – from design and development, through validation and production. With our expertise in automation, we create custom turnkey solutions that drive productivity, meet unique client needs, and are delivered on time. We provide the support and expertise you need to succeed, empowering you to achieve your goals and bring your visions to life. At ASYST Technologies, our dedication to customer satisfaction is unwavering, we listen intently, collaborate relentlessly, and innovate continuously, ensuring that you receive the cutting-edge solutions you need to thrive in today's dynamic marketplace. We understand your unique challenges and can deliver innovative solutions that drive efficiency, reduce costs, and accelerate your time-to-market.Automotive product categories include:

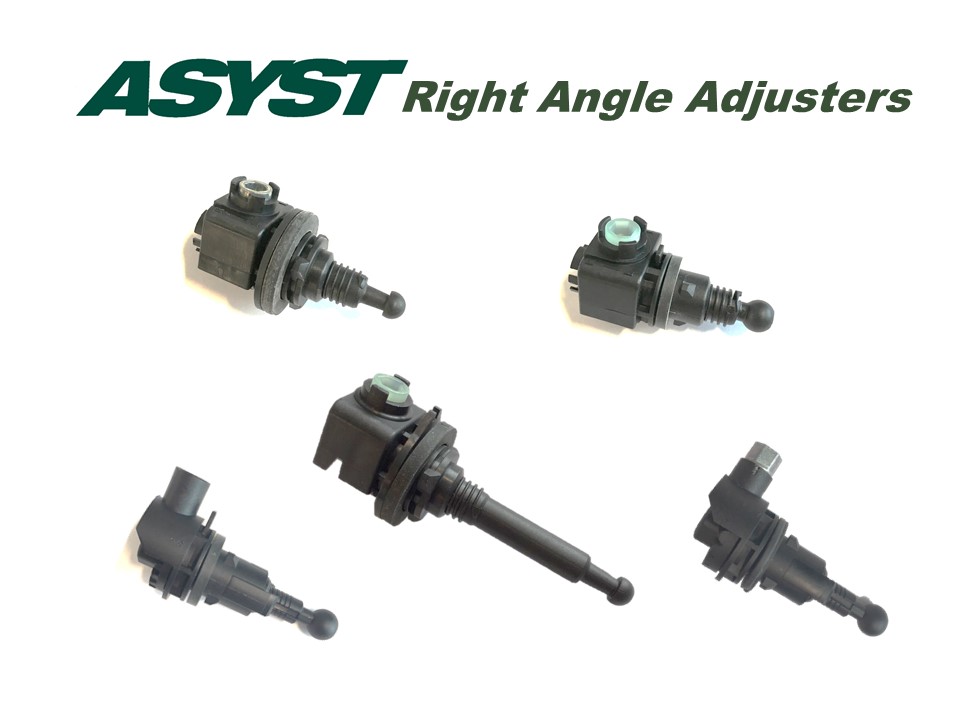

- Manual Right Angle Adjusters with easy installation, clutch features for over-travel protection and low or high torque options. Head Lamp, Tail Lamp, and Fog Lamp Adjustment.

- Leveling Adjusters including Electronic Motor Systems for ECE and 3-position systems for South America.

- Ball Sockets & Tracks with low installation forces and high removal forces of over 440N. These components can installed by Snap-In, Screw-In or Push-In.

- Pivot Studs in plastic or metal.

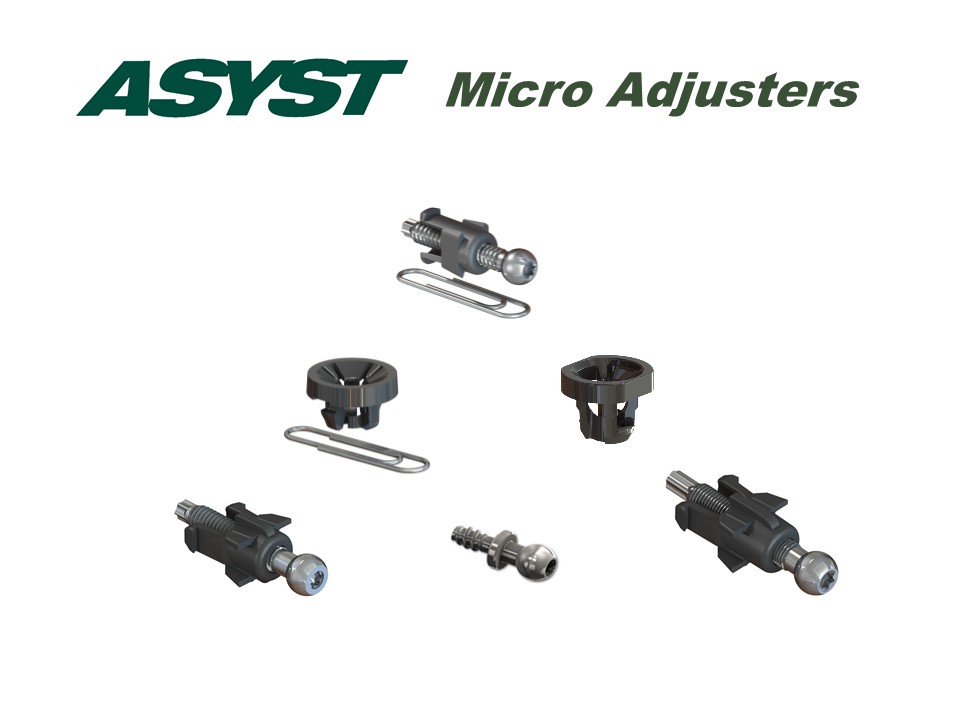

- Micro Adjustment Systems for LED modules.

- Bowden Cables for remote access and flexible aiming.

- Tail Lamp Fasteners with tolerance compensation.

- Plastic Molded "TC" thermally conductive heat sinks are designed and manufactured to provide optimal thermal management for LED lighting applications. The use of "TC" molded heat sinks can provide significant weight and cost advantages over the use of Aluminum heat sinks in LED lighting applications.

- Linkages and more.

Key figures

Revenue:

Private

Number of employees:

180

Company footprint:

Global

Company contact information

Contact Name:

Paul Sutenbach

Vice President Sales

Company location

Company headquarters address:

5811 99th Avenue, Kenosha, Wisconsin, United States 53144